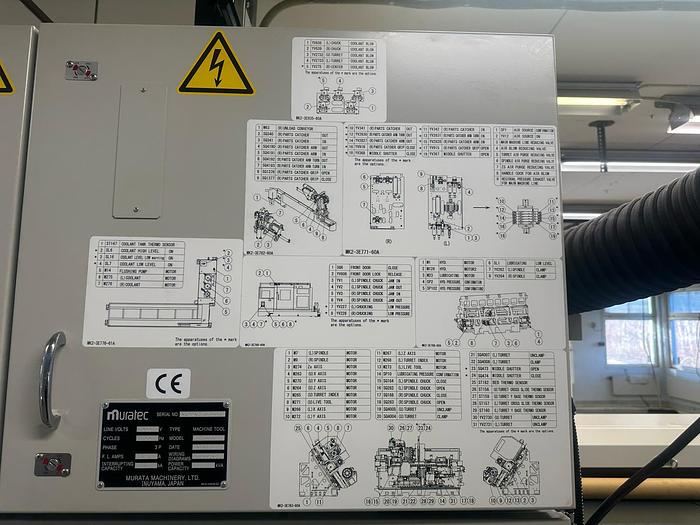

MURATEC CNC LATHE MT200 T2 L-749

Hainbuch Hylschuck TOPlus combi pullback 65 A2-6 (up to 65 mm) including draw pipe adapter, Kitagawa BR208 3-jaw chuck including adapter, hardened jaws, soft jaws.

Short bar magazine LNS Servo 105 including 3 pushers.

Tool package WTO / LNS.

WORKING AREA

Max swing diameter mm 205 (228 with 12-station turret)

Max distance between spindle noses mm 1170

Chuck diameter Ø mm 210

Max bar diameter Ø mm 65

Max workpiece length mm 770

SPINDLE (applicable to both main spindle and sub spindle)

Max spindle speed rpm 4000

Spindle nose JIS A2-6

Drilling Ø mm 77

Spindle bearing diameter Ø mm 110

Spindle motor power kW 15 / 11

AXES

Upper turret X / Z / Y mm 220 / 770 / 80 (+- 40)

Lower turret X / Z / Y mm 200 / 770 / 80 (+- 40)

Right spindle Zs mm 880

Rapid traverse X / Z / Y / Zs m/min 24 / 36 / 12 / 36

TOOL TURRET

Number of tool positions (all driven) 15 + 12

Tool section 20 x 20

Tool section Ø mm 40

Max power for driven tools kW 14.0 (4.8 kW continuous)

Max speed for driven tools rpm 4500

Max tool shank for driven tools Ø mm 16

OTHER

Coolant tank L 380

Hydraulic oil tank L 20

Grease cartridge L 0.7

Coolant pump Bar 3 (option 20 bar)

Power requirement KVA 54

Machine required floor space mm 3550 x 2100 (without chip conveyor)

Net weight std kg 9000 (without coolant tank)

PART CATCHER (with claw and conveyor, option) (only for spindle 2)

Workpiece capacity mm Ø65 x 160 (2.5 kg per part)

REMNANT HANDLING (bucket and box, option) (only for spindle 1)

Remnant capacity mm Ø65 x 100 mm

STANDARD EQUIPMENT:

2 tool turrets with 15 stations upper, 12 stations lower, all positions driven (max 14 kW)

Automatic reference point return for turrets

Y-axis for both turrets

MPG handwheel (0.001 mm, 0.01 mm, 0.1 mm)

Nozzles for coolant and air blowing over both chucks

Foot pedals for chuck operation (open/close), one for each side

Coolant equipment with tank and pump with 3 bar pressure for both sides

LED lighting x 2

Full protective cover

Operator manual

MACHINE PRICE (including the options below):

OPTIONS:

Automatic power off via timer (auto power off) Included

Tool monitoring for both turrets, controlled by torque (tool monitor software) Included

Part ejection detection (via torque sensing for Z2 axis) Included

Signal tower (red / green / yellow) Included

Part catcher (with claw) and part conveyor for spindle 2 Included

Multi-position spindle stop orientation for both sides Included

Through spindle flushing (only spindle #2) Included

Sensor for confirming chuck closure via cylinder stroke length (both spindles) Included

Chip conveyor (slat type) Included

Prepared for oil mist separator (Ø 150 mm) Included

Tool setter for automatic tool measurement (via manual arm, both sides) Included

RS-232C interface Included

20 bar high-pressure flushing for both sides (instead of standard 3 bar) Included

Separate coolant tank Included

2 coolant level switches (one for main tank, one for separate tank) Included

Remnant handling (bucket and box) for spindle 1 Included

Dual coolant filters for both sides (4 total) with switch so filters can be cleaned without interruption Included

Tool offset measurement value direct input B Included

Direct Drawing Dimension programming Included

Hydraulic cylinders VNK150/67 for both spindles for 65 bar (not chucks) Included

Interface for bar feeder Included

Fanuc / Muratec control system

Dual spindles with 4000 rpm, 15 kW

C-axis for both main and sub spindles

Tool station index counter (CRT display, 6 digits, including alarm function)

Part counter, total counter (CRT display, 8 digits)